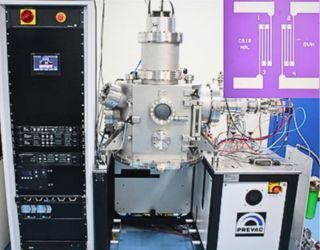

The PREVAC Ion Milling System offers precise etching capabilities, with a range of 100 nm to 100 µm. It uses high-energy Ar⁺ ions, accelerated through a voltage applied to the beam exit grids, allowing for controlled etching with a defined incident angle. The sample rotates at 20°/min to ensure uniform material removal. The system operates at a base pressure of 5 × 10⁻⁷ Torr, and operating pressure is 3 × 10⁻3 Torr. It also provides adjustable ion energy and beam current, making it versatile for various materials including both magnetic and non-magnetic.

Specifications

5×10⁻7 Torr

Compatibility: Vertical and tilt ion bombardment

Wafer size: up to 6-inch wafer process

Materials: Magnetic and non-magnetic

Uniformity: 90% on 4 inch wafer

Ion milling plays a pivotal role in nanotechnology by enabling the fabrication of nanoscale structures and allow for precise patterning at the nanometre scale, essential for nanostructured to microstructure pattern used in sensors and other devices.

Feature of size 100 nm to 100 µm can be achieved.